Repair Kit for short fuel pump 0442201002 and 0010915201 (W113 Fuel Pump)

Rebuild Kit with filter for W113 Fuel Pump

for Bosch Electric Fuel Pump

1965-1972 Mercedes-Benz 280SE 280SEL,280SL 600

0 442 201 002

A0010915201

When it comes to maintaining a classic car like the Mercedes-Benz 280SL, also known as the “Pagoda,” preserving its original components is crucial to its value and performance. One of the most critical components in the 280SL is the Bosch fuel injection pump (W113 fuel pump), model number 0010915201, which controls the precise fuel delivery to the engine. Over time, wear and tear take their toll on this part, leading to the need for a rebuild. A rebuild kit specifically designed for this model can restore the W113 fuel pump to its original efficiency and ensure your vehicle runs smoothly for years to come. In this article, we’ll walk through the importance of the Bosch pump, the benefits of using a rebuild kit, and the essential steps involved in the rebuilding process.

What is the Bosch Fuel Injection Pump?

The Bosch fuel injection pump installed in the Mercedes 280SL is a mechanical pump that plays a vital role in controlling fuel flow to the engine. It is responsible for maintaining the ideal air-fuel mixture, ensuring the engine runs efficiently. Unlike modern fuel injection systems that are electronically controlled, the Bosch 0010915201 (W113 fuel pump) is a mechanical masterpiece that requires precision engineering to operate correctly. Given its complexity, issues like wear in the pump’s plungers, seals, and other internal components can lead to reduced engine performance, hard starts, poor fuel economy, or even engine failure. Rebuilding this pump with a specialized rebuild kit is often the best and most cost-effective solution to restore the 280SL to its former glory.

Why Use a Rebuild Kit for the W113 Fuel Pump?

A rebuild kit for the Bosch fuel injection pump contains all the necessary seals, gaskets, springs, and other critical components needed to bring the pump back to factory specifications. The advantages of using a rebuild kit are numerous:

- Cost-Effectiveness: A new fuel injection pump can be prohibitively expensive, particularly for classic cars where original parts are either rare or costly. Rebuilding the pump using a kit is a much more economical option.

- Restoring Original Functionality: The rebuild kit allows you to restore the Bosch pump to its original working condition, ensuring that it maintains the precise fuel flow and timing engine requirements call for.

- Preserving Authenticity: For collectors and enthusiasts, maintaining the authenticity of a classic car is essential. A rebuild kit ensures that the original pump can continue functioning without replacing it with a less authentic part.

- Extended Lifespan: Replacing worn components can extend the life of the W113 fuel pump and, by extension, the engine itself, giving you more years of reliable performance from your 280SL.

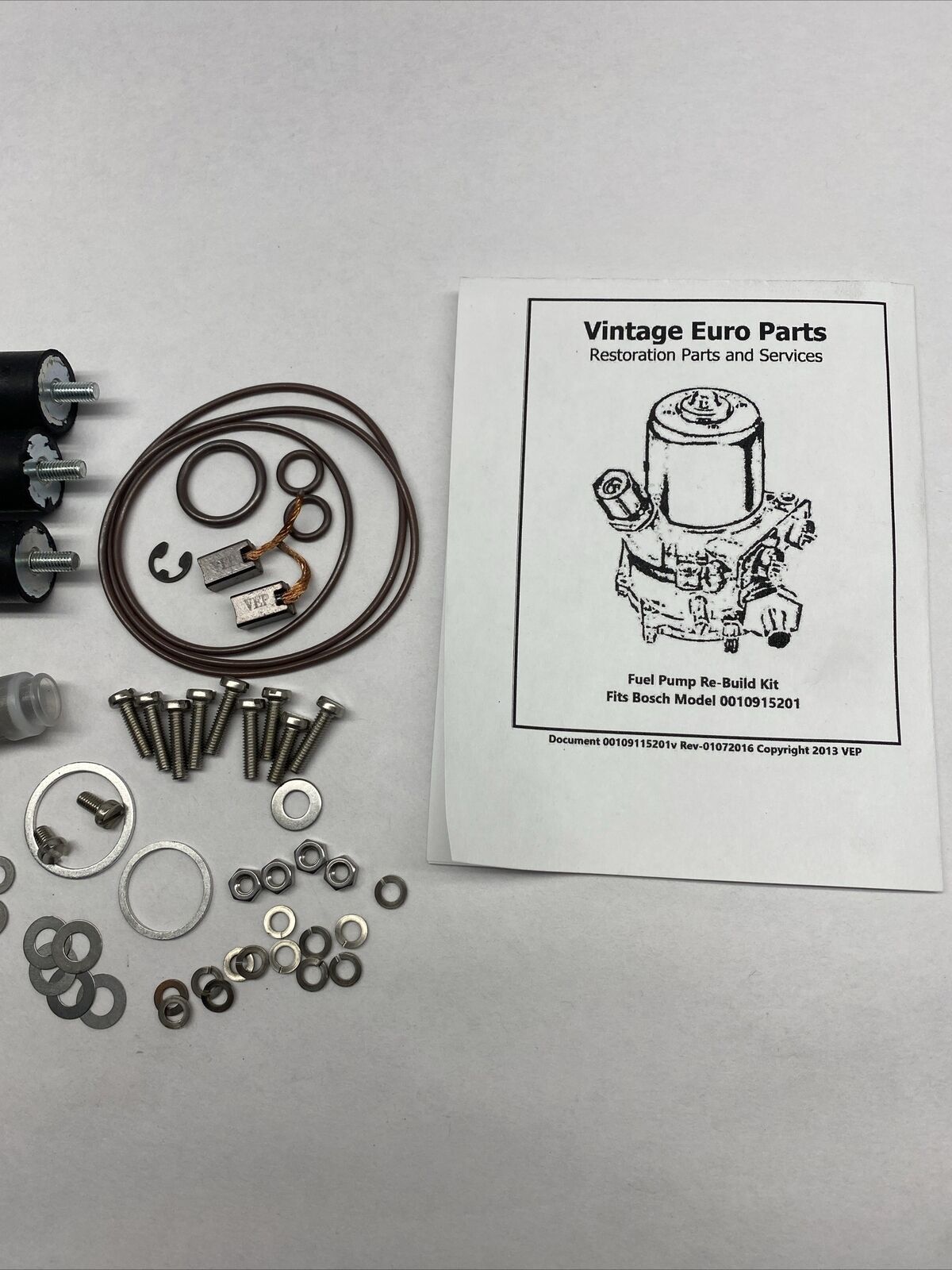

Components of a Rebuild Kit for the Bosch 0010915201 Pump

A typical rebuild kit for the Bosch 0010915201 (W113 fuel pump) includes a range of components designed to address common areas of wear and tear. These components typically include:

- Seals and Gaskets: The seals and gaskets within the pump wear out over time due to exposure to heat, fuel, and contaminants. New seals ensure that there are no leaks, which can lead to loss of pressure and poor fuel delivery.

- O-Rings: O-rings provide a critical seal between various components within the pump. Over time, these can become brittle and crack, leading to leaks. A rebuild kit contains O-rings that meet or exceed the original specifications.

- Plunger Springs: The plungers inside the pump are responsible for delivering fuel to the engine. The springs control their movement, and over time, they can lose tension, leading to inconsistent fuel delivery. New springs restore the proper tension and performance.

- Check Valves: These valves help control the flow of fuel within the W113 fuel pump. They can become clogged or damaged over time, leading to poor performance or a complete failure of the pump. Replacing these ensures optimal fuel flow.

- Copper Washers: Copper washers are often used to seal various connections in the pump. These can become worn or corroded, leading to leaks. The rebuild kit provides replacements for these washers.

- Shaft Seals: The main shaft of the pump has seals that prevent oil or fuel from leaking out. These seals are critical for maintaining pressure within the pump and preventing external leaks.

Steps for Rebuilding the Bosch W113 Fuel Pump

Rebuilding the Bosch fuel injection pump requires a certain level of mechanical expertise, but it can be accomplished with patience and attention to detail. Here’s a step-by-step guide to help you understand the process:

- Disassembly of the Pump: Begin by carefully disassembling the fuel injection pump. Keep track of each component, noting its orientation and position for reassembly. It’s important to work in a clean environment, as any contamination can damage the pump during reassembly.

- Cleaning and Inspection: Once disassembled, thoroughly clean each part of the pump. Inspect each component for wear, cracks, or corrosion. Replace any parts that are not included in the rebuild kit but show signs of damage.

- Replacing Seals and Gaskets: Install the new seals and gaskets from the rebuild kit. These parts are vital for preventing fuel leaks and maintaining the necessary pressure inside the W113 fuel pump. Be sure to lubricate any seals or O-rings with a fuel-compatible lubricant before installation.

- Installing New Springs and Valves: Replace the old plunger springs and check valves with the new ones from the rebuild kit. These components are critical for maintaining the correct fuel delivery rate. Ensure that all springs are seated properly and that the plungers move freely.

- Reassembly: Carefully reassemble the pump, making sure that each part is in the correct orientation. Torque all bolts and fasteners to the manufacturer’s specifications to avoid any issues during operation.

- Testing the W113 Fuel Pump: Once reassembled, it’s important to test the pump before installing it in the vehicle. A specialized fuel pump testing rig can simulate engine conditions, allowing you to verify that the pump delivers fuel correctly at all RPM ranges.

- Reinstallation and Final Testing: After confirming the pump is operating properly, reinstall it into your Mercedes 280SL. Once installed, run the engine and check for any leaks, unusual noises, or performance issues. Adjust the pump timing as necessary to ensure optimal performance.

Conclusion

Rebuilding the Bosch 0010915201 fuel injection pump (W113 fuel pump) on a Mercedes 280SL can seem daunting, but with the right rebuild kit and a methodical approach, it’s entirely possible to restore this critical component to its original function. By using a rebuild kit, you’ll save money, maintain authenticity, and extend the life of your classic vehicle. Whether you’re a DIY enthusiast or a professional mechanic, understanding the importance of the Bosch pump and the rebuild process is key to keeping a Mercedes 280SL running smoothly for years to come.